AES idlers are now available for a wide range of applications and belt widths. These reliable, high quality idlers are used by OEM conveyor manufacturers as well as sand & gravel / mineral mining operations. AES offers the best value idler line on the market with a product mix comprised of 4 inch CEMA “B”, 5 inch CEMA “C”, and 6 inch CEMA “D” idlers, available in troughing, return, impact, training, channel mount, & picking styles.

AES 35-30 Troughing Idler

What Makes AES Idlers the Best Choice?

AES Roller Cutaway

- Industry-preferred, recessed end disk eliminates roll-to-end disc separation.

- Grease filled deep labyrinth seal helps eliminate contaminants within bearing.

- Exterior shield provides a barrier and keeps contaminants from bearing cavity.

- Precision ground, lifetime greased ball bearings with positive lip contact seals.

- Heavy wall cans with Blu-Maxx powder finish

AES Speed Reducers Offer Great Value

- AES speed reducers feature precision machined, corrosion resistant, ductile cast iron housings.

- Strong, ribbed housing design protects working bearings & gearing.

- Oil channels to all bearings for superior lubrication and extended operating life.

- Double lip gear tooth design maximizes power transfer efficiency.

AES Speed Reducer

- AES reducers mount directly on the drive shaft thus eliminating the need for a coupling or chain drive.

- Sliding motor base and support structure eliminate alignment problems.

- Twin taper bushings eliminate play between the reducer and shaft.

- No set screws to score or gouge the shaft.

- Torque arm can be positioned anywhere along the driven shaft in horizontal, vertical and inclined positions.

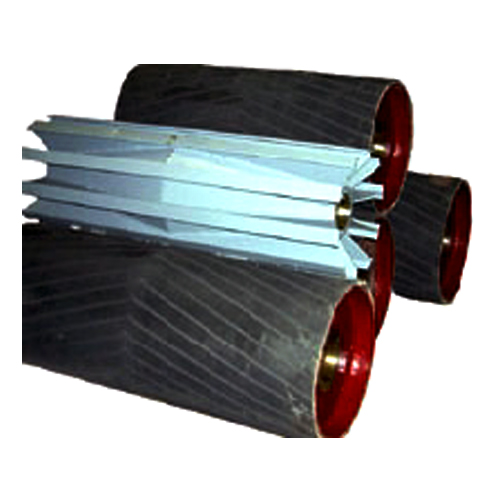

Pulleys

AES pulley options include lagged drum style as well as heavy duty aggregate & mine duty wing pulleys. Smooth Steel Drum Pulleys are also available. AES pulleys feature XT hubs & bushings and high strength end discs.

AES Lagged Head Pulley

Wing & Drum Pulleys